Cutting Dies

Certified DIE-MAKER by Bobst

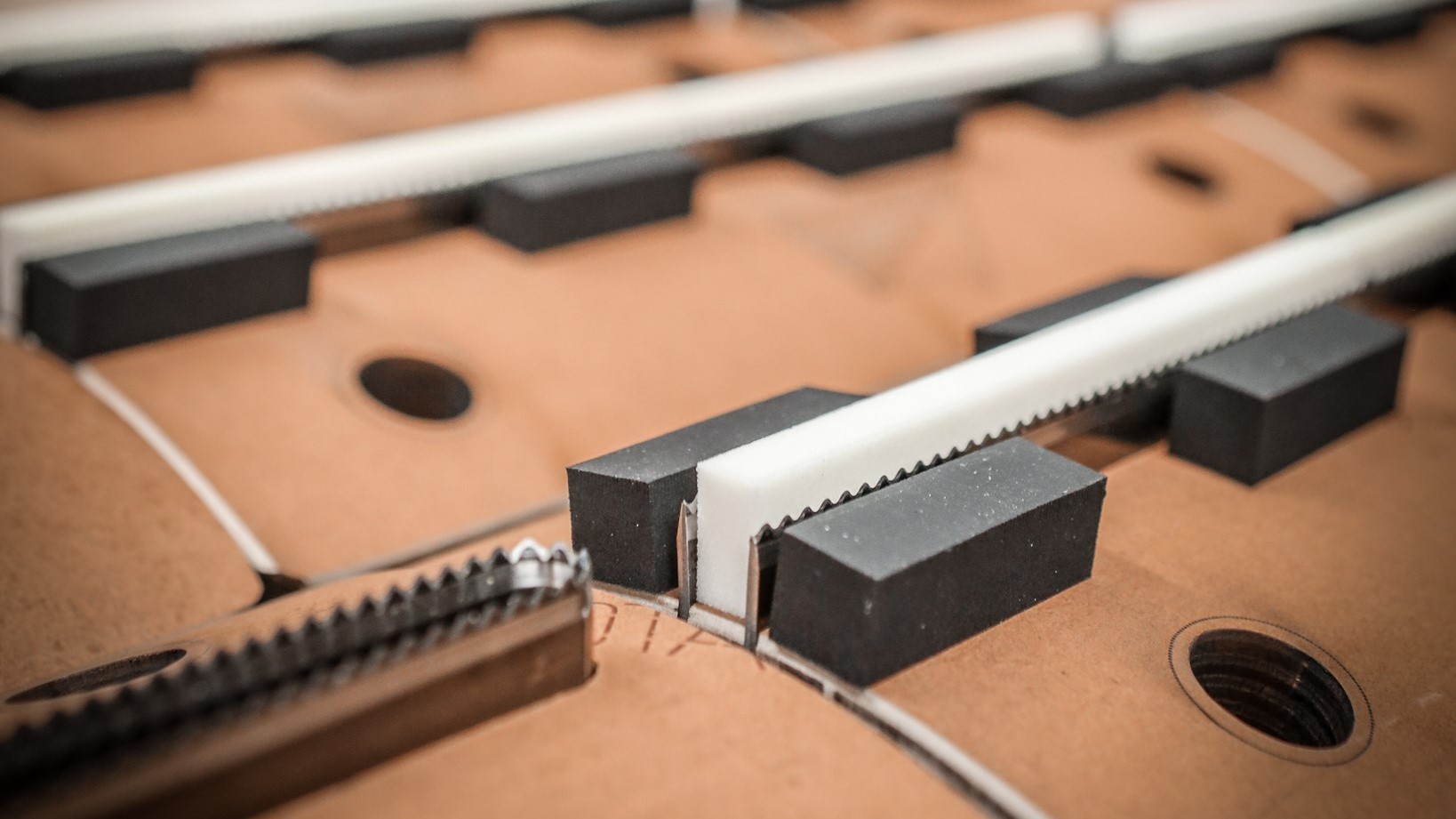

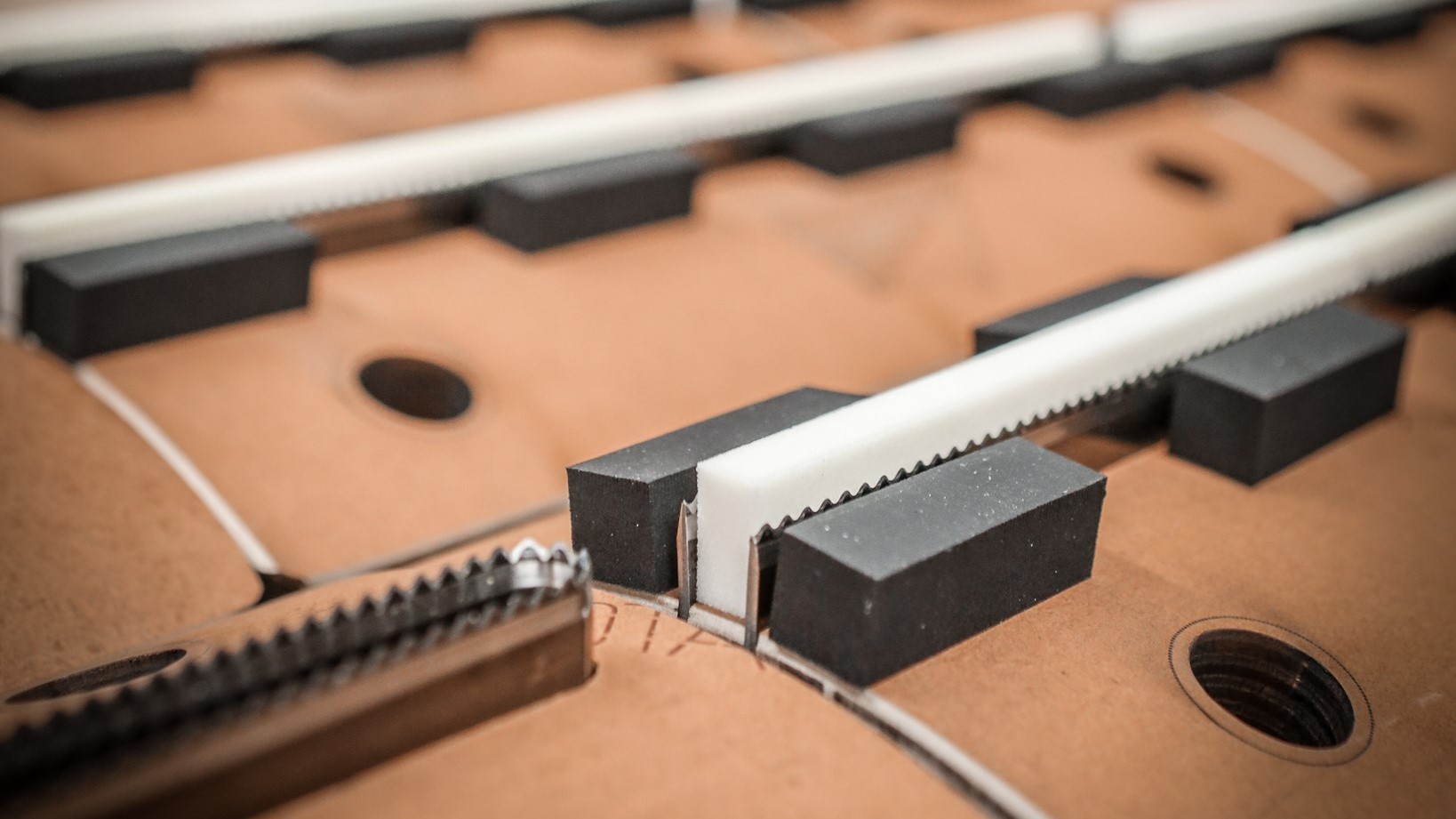

Industrial cutting dies

We at Gerdins have a long experience of diecutting in demanding materials. Our cutting tools produce details for the industry with the highest accuracy, regardless of whether it is a gasket for the automotive industry, a foam interior for box or a detail for the electronics industry.

If you are going to produce knee pads, seat cushions or sound absorbers, we also manufacture complete molding tools in aluminum or prototype material.

Corrugated cutting dies

For die cutting in corrugated board, Gerdins offers high-class tooling solutions, both in terms of flatbed and rotary tools.Quality, function and overall economy are in focus wellstansar.

Cardboard Cutting dies

Quality and function are the focus of our cardboard tools. Gerdins can provide the optimal tool solution that suits your machine and material. This results in short intake times and high safety.

We only use the highest quality plywood, cutting lines and rubber in our tools, we know that choosing the right material is critical to good function.

Industrial cutting dies

We at Gerdins have a long experience of diecutting in demanding materials. Our cutting tools produce details for the industry with the highest accuracy, regardless of whether it is a gasket for the automotive industry, a foam interior for box or a detail for the electronics industry.

If you are going to produce knee pads, seat cushions or sound absorbers, we also manufacture complete molding tools in aluminum or prototype material.

Corrugated cutting dies

For die cutting in corrugated board, Gerdins offers high-class tooling solutions, both in terms of flatbed and rotary tools.Quality, function and overall economy are in focus .

Cardboard Cutting dies

Quality and function are the focus of our cardboard tools. Gerdins can provide the optimal tool solution that suits your machine and material. This results in short intake times and high safety.

We only use the highest quality plywood, cutting lines and rubber in our tools, we know that choosing the right material is critical to good function.

More information

What are cutting dies?

Cutting dies represent a component of modern manufacturing and design, and form the basis of some industrial and artisanal processes. These specialized tools play a critical role in the ability to quickly and efficiently create holes, cutouts or specific shapes in a variety of materials. Using the punching process, where a sharp, custom tool is pressed through the material, enables the creation of detailed and precision-demanding components with a high degree of accuracy and consistency.

Cutting dies typically work through the use of a press, or punch, to drive the punching tool through the material. This force must be carefully controlled and adapted to the properties of the material to avoid damage to the tool or the processed material. The sharp tool/knives often made of steel are tailored to match the desired shape and size of the cut.

How to choose the right cutting dies?

Choosing the right cutting die requires careful consideration of the properties of the material to be processed, the desired shape and the volume of production. It is important to understand the thickness, hardness and flexibility of the materials in order to choose a tool that can deliver high precision and long life.

Areas of use

Stansverktyg från Gerdins Cutting Technology är mångsidiga och kan användas inom en rad olika områden, från tillverkning av förpackningsmaterial till komponenter i plast. Våra verktyg är idealiska för att skapa rena och precisa utskärningar i material som kartong & olika plasttyper. Tillämpningar inkluderar allt från industriell produktion av fordonstillbehör och elektroniska komponenter till skapande av specialförpackningar och reklammaterial. Här är en lista över några av de mest framträdande användningsområdena:

- The packaging industry: Cutting dies are used to create custom packaging, including blister packs, carton packs and other specialty packaging. These tools enable precise cutting of packaging materials to create windows, holes, and unique shapes that meet specific product presentations and functionality requirements.

- Automotive industry: In the automotive industry, punching tools are used to produce components such as seals, insulation, and other parts that require precision cutting of materials such as rubber, plastic, and thin metals.

- Advertising and marketing materials: Cutting dies are used to create unique promotional materials, such as business cards, brochures, and display materials with special cutouts and shapes that capture the customer's attention.

- The construction industry: In the construction sector, punching tools are used to cut out components for building materials, such as ventilation ducts and insulation materials. This also includes precision cutting of decorative elements or functional components in different materials.

- The textile and leather industry: For the manufacture of clothing, shoes, and accessories where precision cutting of textiles or leather materials is required, punching tools are used to streamline production and ensure high quality of the end products.

What materials can our tools process?

Our cutting dies are designed to handle a wide range of materials. This includes:

- Cardboard: Ideal for the packaging industry, where precise cutouts are required to create custom packaging solutions.

- Plastic: Includes a wide range of plastics, from thin films to thicker plastic sheets, for use in packaging, medical devices, and more.

- Rubber: Our cutting dies can cut different thicknesses of rubber for the manufacture of seals, gaskets and other industrial components.

- Foam material: Ideal for insulation, protective packaging and sound absorbing applications.

- Leather: Used to create precision cutouts for shoes, bags, and other leather products.

- Composite Material: Out cutting dies can also be used to process various composites, enabling the manufacture of advanced components for specific industrial applications.

Our commitment to quality and precision ensures that regardless of the material, our tools deliver consistent and reliable results that meet the high demands of our customers.

SPECIAL PRODUCTION - AT THE LEADING EDGE

Gerdins Cuttning Technology has over the years continuously invested in new machines with the latest technology. This means that the production with our high-tech machines are in principle fully computer controlled.

When designing the punching tools, the very latest CAD technology is used, which is fully integrated into the production equipment. This applies to everything from laser cutters and automatic cutting and bending machines for processing punched steel to plotters/test tables, milling machines and cutting tables for the ejector rubber as well as automatic equipment for the manufacture of cleaning tools.

LONG-TERM GROWTH

Besides supplying the cutting dies and punches of the highest quality we build our business on integrity and ethical attitude to business. By working closely with you as a customer, we believe that together we can create a long-term growth. As a partner to our customers, it is natural for us to contribute to the competitiveness of the entire life cycle. All our business areas can offer a customer the appropriate mix of engineering, manufacturing and logistics.

BOBST DIE-MAKER CERTIFICATION PROGRAM

Why choose a Certified Die-maker? Converters need to be confident that their die-makers have the skills, understanding and equipment required to produce high-quality dies - the BOBST Die-maker Certification Program is a guarantee of excellence. Every BOBST-certified die-maker has been identified as having a positive, forward-thinking attitude towards quality standards, innovation, automation and digitalization, ensuring they possess the mindset and approach to production that converters ask for.

When we started the certification process, our ability, knowledge and understanding of the entire tooling process was evaluated by a BOBST tooling specialist, which helped us at Gerdins to ensure that we are working correctly and optimizing our equipment to produce excellent tools.

Finally, now that we are certified, BOBST provides a wide range of support systems and exclusive products – everything we need to provide our customers with the best tools.